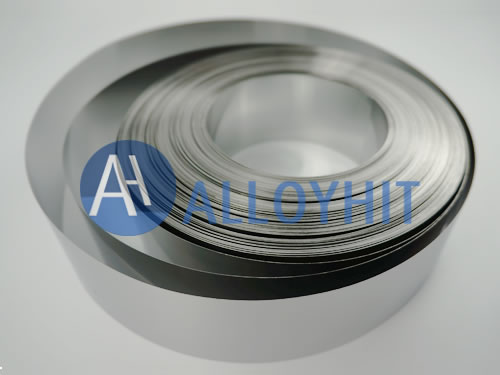

AlloyHit produces the world's finest ultra-thin Niobium Foil with purity exceeding 99.95%. Our proprietary rolling technology enables us to achieve consistent thicknesses of Niobium Foil down to 0.02mm with remarkable uniformity across large surface areas.

Each Niobium Foil is meticulously manufactured under strict cleanroom conditions to ensure exceptional surface quality and freedom from defects. This level of precision makes our Niobium Foil indispensable for advanced technological applications.

Ultra-Thin Capability

From 20μm to 100μm thickness

Uniform Thickness

±1μm tolerance achievable

High Purity

99.95%, 99.99%, 99.995%+ Niobium content

Superior Surface

Ra < 0.1μm surface finish

Technical Specifications of Niobium Foil

Our Niobium Foil meets the most stringent technical requirements for advanced industrial applications

| Property | Specification | Test Method |

| Thickness Range | 20μm - 100μm (0.005mm - 0.1mm) | Laser Profilometry |

| Thickness Tolerance | ±1μm (for foils <50μm) | Laser Profilometry |

| ±2μm (for foils >50μm) | ||

| Width Range | 10mm - 600mm | Precision Calipers |

| Length Range | 100mm - 5000mm or in coils | Laser Measuring System |

| Purity | ≥99.95% | GDMS / ICP-MS |

| Surface Roughness | Ra < 0.1μm (typical) | Atomic Force Microscopy |

| Tensile Strength | 240-340 MPa | ASTM E8 |

| Melting Point | 2468°C (4474°F) | Differential Thermal Analysis |

Custom Sizes

We offer custom dimensions beyond standard specifications to meet your unique application requirements.

Surface Treatments

Various surface finishes available including electropolishing, annealing, and passivation treatments.

Packaging Options

Specialized cleanroom packaging available to ensure contamination-free delivery and handling.

Manufacturing Capabilities of Niobium Foil

Advanced production technology that enables us to achieve exceptional thinness and quality of Niobium Foil.

Precision Rolling

State-of-the-art rolling mills with micron-level control, enabling us to produce consistently thin Niobium Foil with exceptional flatness.

Cleanroom Processing

Class 1000 cleanroom facilities ensure minimal contamination during all stages of production and handling of Niobium Foil.

Advanced Inspection

Laser-based thickness measurement systems and automated optical inspection for 100% quality verification of Niobium Foil.

Our Quality Commitment of Niobium Foil

We maintain the most rigorous quality control standards throughout the manufacturing process. Each batch of niobium foil undergoes comprehensive testing to ensure it meets our exacting specifications.

Applications of Niobium Foil

Our ultra-thin Niobium Foil enables innovation in advanced technological applications

Aerospace

Niobium Foil can be lightweight, high-temperature components for advanced aerospace systems and propulsion technologies.

Medical Devices

Niobium Foil can be used in precision medical instruments and diagnostic equipment where biocompatibility and thinness are critical.

Superconductors

Niobium Foil can be critical component in superconducting magnets and devices due to niobium's excellent superconducting properties at cryogenic temperatures.

Semiconductors

Niobium Foil can be precision components in semiconductor manufacturing equipment and high-performance electronic devices.

Energy Storage

Niobium Foil can be advanced battery technologies and energy storage systems requiring high-purity, thin metal components.

Scientific Research

Niobium Foil can be essential material for nuclear fusion research, particle physics experiments, and advanced material science.

Global Supply Capability of Niobium Foil

We serve customers worldwide with reliable delivery and comprehensive technical support of Niobium Foil.

Worldwide Distribution

Exporting to 30+ countries with established logistics partners for reliable international shipping

Specialized Packaging

Custom packaging solutions to ensure ultra-thin Niobium Foil arrives in perfect condition anywhere in the world.

Documentation

Comprehensive certification packages including material certificates, test reports, and compliance documentation.

Technical Support

Multilingual engineering support to assist with application development and technical requirements of Niobium Foil.

Request Information

Our technical specialists are ready to assist with your ultra-thin Niobium Foil requirements

+86 13120915623

+86 13120915623