Ti-6Al-4V (Ti Grade 5) Rod & Bar

Ti-6Al-4V (Ti Grade 5) Rod & Bar are the most widely used titanium alloy product form, valued for their exceptional strength-to-weight ratio and corrosion resistance.

Ti-6Al-4V (Ti Grade 5) Rod & Bar stock is an alpha-beta titanium alloy containing 6% aluminum and 4% vanadium. This alloy combines high strength with excellent fatigue resistance, making it ideal for applications requiring both structural integrity and lightweight properties.

With a tensile strength ranging from 900-1100 MPa and a density of only 4.43 g/cm3³, Ti-6Al-4V bars offer one of the highest strength-to-weight ratios among engineering materials, exceeding that of most stainless steels while providing superior corrosion resistance.

High Strength-to-Weight

Superior ratio compared to steel and aluminum

Corrosion Resistant

Excellent performance in harsh environments

Temperature Resistant

Maintains strength up to 400°C (752°F)

Biocompatible

Ideal for medical implant applications

Mechanical & Physical Properties of Ti-6Al-4V (Ti Grade 5) Rod & Bar

Ti-6Al-4V (Ti Grade 5) Rod & Bar exhibit exceptional mechanical properties that make them suitable for high-performance structural applications.

Mechanical Properties

Annealed condition, room temperature

0.2% offset, annealed condition

In 50 mm, annealed condition

Tonsile, room temperature

Rockwell C scale

At 10^7 cycles, room temperature

Physical Properties

Approximately 60% of steel's density

Liquidus temperature

At 20°C (68°F)

From 20-100°C (68-212°F)

Room temperature

Specifications of Ti-6Al-4V (Ti Grade 5) Rod & Bar

Our Ti-6Al-4V (Ti Grade 5) Rod & Bar are available in various diameters, lengths, and finishes to meet your specific application requirements.

| Diameter Range | Length Range | Bar Types | Tolerance | Surface Finish | Condition |

| 3 mm-300 mm | 1000 mm-6000 mm | Round bars | h9, h10, h11 (DIN) | Hot rolled | Annealed |

| Square bars | -0.05/+0.1 mm (standard) | Cold drawn | Solution treated and aged | ||

| Hexagonal bars | Tighter tolerances available | Ground | Mill finish | ||

| Rectangular bars | Polished | ||||

| Custom diameters available | Cut-to-length available | Custom profiles on request | Precision tolerance (±0.01 mm) available for critical applications | Special finishes available | Custom heat treatments available |

Precision Sizing

Tight diameter tolerances ensure consistent machining results and reduced material waste.

Multiple Profiles

Available in round, square, hexagonal, and custom profiles to meet diverse design requirements.

Quality Assurance

Each bar undergoes rigorous inspection for dimensional accuracy and surface quality.

Cut-to-Length

We can provide bars cut to your exact length requirements, reducing processing time.

Ti-6Al-4V (Ti Grade 5) Bar Type Visualization

Our Ti-6Al-4V (Ti Grade 5) bars are available in various cross-sectional profiles to suit different application needs:

Manufacturing & Processing of Ti-6Al-4V (Ti Grade 5) Rod & Bar

Our Ti-6Al-4V (Ti Grade 5) Rod & Bar undergo a precise manufacturing process to ensure consistent quality and performance.

1. Alloy Production

High-purity titanium sponge is combined with aluminum and vanadium master alloys in precise proportions. The mixture is pressed into electrodes and vacuum arc melted multiple times to ensure chemical homogeneity.

2. Ingot Forging

The titanium alloy ingot is heated to beta phase temperature (above 995°C) and forged into round billets using a series of hot working operations to break down the cast structure and improve mechanical properties.

3. Hot Rolling

The billets are heated to 800-900°C and hot rolled into bar stock using a series of passes, gradually reducing diameter while maintaining the material in the alpha-beta phase field for optimal microstructure development.

4. Cold Drawing & Finishing

For improved dimensional accuracy and surface finish, cold drawing is performed. This process reduces diameter while work-hardening the material, followed by annealing to achieve the desired mechanical properties.

5. Precision Grinding & Inspection

The bars undergo precision grinding to achieve tight dimensional tolerances and superior surface finish. Each bar is inspected for dimensional accuracy, surface quality, and mechanical properties.

Machining Guidelines for Ti-6Al-4V (Ti Grade 5) Rod & Bar

Ti-6Al-4V (Ti Grade 5) Rod & Bar can be machined using conventional methods, but require special considerations due to the material's unique properties:

Use carbide tools with positive rake angles designed specifically for titanium

Maintain cutting speeds of 30-60 m/min for roughing, 60-120 m/min for

finishing

Use high-pressure coolant systems (70-100 bar) to prevent workpiece heating

Employ rigid setups and minimize tool overhang to prevent vibration

Use lower feed rates (0.1-0.2 mm/rev) compared to steel machining

Consider using oil-based coolants for improved lubrication and heat transfer

International Standards of Ti-6Al-4V (Ti Grade 5) Rod & Bar

Our Ti-6Al-4V (Ti Grade 5) Rod & Bar meet or exceed the requirements of major international standards, ensuring quality and performance.

Material Standards

-

ASTM B348

Standard Specification for Titanium and Titanium Alloy Bars and Billets -

EN 10204 3.1

Material certification with test results from an independent laboratory

Quality Management

Our manufacturing facilities are certified to the following quality management systems:

Quality Management Systems

Aerospace Special Processes

Certification & Traceability

Every batch of Ti-6Al-4V (Ti Grade 5) Rod & Bar comes with comprehensive documentation ensuring full traceability from raw material to finished product:

- Material certification with chemical composition analysis

- Mechanical properties test results (tensile, hardness)

- Heat treatment records and process parameters

- Dimensional inspection reports

- Ultrasonic testing reports for internal soundness

- Microstructural analysis (when required)

Custom Testing Available

We can provide additional testing and certification as required by your specific application, including fatigue testing, corrosion testing, and more. Please contact us with your specific requirements.

Hardness of Ti-6Al-4V(Ti Gr.5) Rods

- Room temperature hardness in annealed state HBS=255~341

- Room temperature hardness in solution aging state HBS=293~361

Mechanical properties of Ti-6Al-4V(Ti Gr.5) Rods

| Performance as specified by technical standards Ti-6Al-4V Rods | |||||||||||

| Type | State | δ or d /mm | Sampling direction | σb/MPa | Room temperature | 400℃ | |||||

| τp02/MPa | δ5/% | φ/% | αKU/kJ·m-2 | α/(º) | σb/MPa | σ100/Mpa | |||||

| ≥ | |||||||||||

| Rods | Annealed | 8~90 | L | ≥895 | 825 | 10 | 25 | 400 | - | 620 | 570 |

| Rods | Annealed | ≤50 | L | ≥930 | 860 | 10 | 25 | 400 | - | 590 | 570 |

| Rods | Annealed | 51~70 | ≥895 | 825 | 10 | 25 | 400 | - | 590 | 570 | |

| Rods | Annealed | 21~50 | L | ≥930 | 860 | 10 | 25 | - | - | 615 | 570 |

| Rods | Annealed | >50~75 | L | ≥895 | 825 | 10 | 25 | - | - | 615 | 570 |

| Rods | Annealed | >75~100 | L | ≥895 | 825 | 10 | 25 | 345 | 615 | 570 | |

| Rods | Annealed | LT | ≥895 | 825 | 95 | 20 | - | - | 615 | 570 | |

| Rods | Annealed | >100~150 | L | ≥895 | 825 | 10 | 25 | 295 | - | - | - |

| Rods | Annealed | LT | ≥895 | 825 | 9 | 20 | - | - | 600 | 560 | |

| Rods | Annealed | >150~220 | L | ≥895 | 825 | 10 | 20 | - | - | - | - |

| Rods | Annealed | LT | ≥895 | 825 | 8 | 18 | - | - | - | - | |

| Rods | Annealed | 21~100 | L | ≥895 | 825 | 10 | 25 | - | - | - | - |

| Rods | Annealed | >100~150 | C | ≥895 | 825 | 9 | 20 | - | - | - | - |

| Rods | Annealed | >150~220 | C | ≥895 | 825 | 8 | 15 | - | - | - | - |

Tensile properties of Ti-6Al-4V(Ti Gr.5) Rods

| Tensile properties of Ti-6Al-4V(Ti Gr.5) Rods | |||||||||

| Type | d/mm | State | Sampling direction | θ/℃ | σb/MPa | σp0.2/MPa | σp0.1/MPa | δ5/% | φ/% |

| Rods | 20 | Annealed | L | -55 | 1059 | - | - | 16.8 | 39.1 |

| -30 | 1020 | - | - | 17.7 | 44.5 | ||||

| 20 | 967 | 860 | 836 | 16.2 | 44.1 | ||||

| 100 | 846 | 736 | 695 | 15.4 | 49.3 | ||||

| 200 | 741 | 613 | 578 | 17.4 | 54.8 | ||||

| 300 | 690 | 643 | 501 | 17 | 58.9 | ||||

| 350 | 665 | 532 | 498 | 16.1 | 58.1 | ||||

| 400 | 645 | 508 | 474 | 17.3 | 60.1 | ||||

| 500 | 583 | 401 | 350 | 26.5 | 78.1 | ||||

| 600 | 413 | 212 | 178 | 47.9 | 93.8 | ||||

| 700 | 245 | 89 | 72 | 118 | 99 | ||||

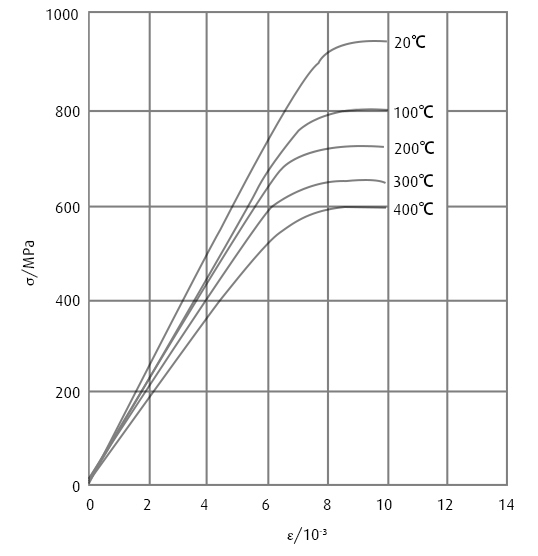

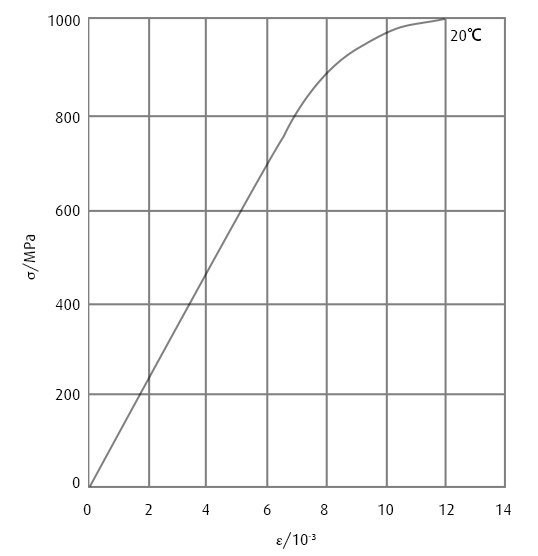

Tensile stress-strain curves of Ti-6Al-4V(Ti Gr.5) Rods

Compression performance of Ti-6Al-4V(Ti Gr.5) Rods

| Compressive yield strength of Ti-6Al-4V(Ti Gr.5) Rods at room temperature | |||||

| Type | d/mm | State | Sampling direction | θ/℃ | σpc0.2/MPa |

| Rods | 18 | Annealed | L | 20 | 969 |

| High temperature creep properties of Ti-6Al-4V(Ti Gr.5) Rods | ||||||

| Type | d or δ /mm | State | Sampling direction | θ/℃ | σ0.1/100/MPa | σ0.2/100/MPa |

| Rods | 20 | Annealed | L | 300 350 400 |

530 392 177 |

579 471 235 |

| Rotational bending fatigue limit of Ti-6Al-4V(Ti Gr.5) Rods | ||||||||

| Type | d /mm | State | Sampling direction | θ/℃ | Kt | R | N/circle | σD/MPa |

| Rods | 24 | Annealed | L | 20 | 1 1.72 |

-1 -1 |

2 X 107 2 X 107 |

481 275 |

| 200 | 1 1.72 |

-1 -1 |

2 X 107 2 X 107 |

432 265 |

||||

| 300 | 1 1.72 |

-1 -1 |

2 X 107 2 X 107 |

422 235 |

||||

| 400 | 1 1.72 |

-1 -1 |

2 X 107 2 X 107 |

412 206 |

||||

| Static and dynamic elastic moduli of Ti-6Al-4V(Ti Gr.5) Rods | ||||||

| Type | d /mm | State | Sampling direction | θ/℃ | E/GPa | ED/GPa |

| Rods | 20 | Annealed | L | 20 | 109 | 112 |

| 50 | - | 111 | ||||

| 100 | - | 110 | ||||

| 150 | 97 | 107 | ||||

| 200 | - | 104 | ||||

| 250 | 91 | 102 | ||||

| 300 | - | 98 | ||||

| 350 | 85 | 95 | ||||

| 400 | - | 92 | ||||

| 450 | 75 | - | ||||

| Shear modulus of Ti-6Al-4V(Ti Gr.5) Rods | |||||

| Type | d /mm | State | Sampling direction | θ/℃ | G/GPa |

| Rods | 20 | Annealed | L | 20 | 44 |

| 100 | 43 | ||||

| 200 | 41 | ||||

| 300 | 38 | ||||

| 400 | 36 | ||||

| 500 | 34 | ||||

| 600 | 32 | ||||

Custom Testing Available

We can provide additional testing and certification as required by your specific application, including fatigue testing, corrosion testing, and more. Please contact us with your specific requirements.

+86 13120915623

+86 13120915623