Extreme Temperature Resistance

With a melting point of 2468°C (4474°F), Niobium Wire maintains structural integrity in high-temperature environments.

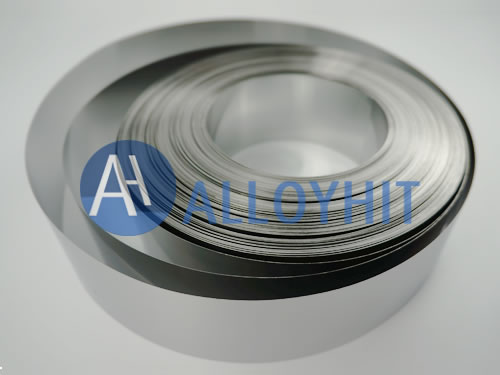

Alloy Hit produces high-precision Niobium Wire from 99.95%+ pure Niobium. Our advanced drawing process achieves consistent diameters from 0.1mm up to 5mm with remarkable uniformity and surface quality.

Each wire is manufactured under strict quality controls to ensure exceptional mechanical properties and freedom from defects. Our niobium wire maintains its integrity in extreme temperatures and harsh environments, making it ideal for critical applications.

From 0.1m to 5mm

±1μm tolerance available

99.95%, 99.99%, 99.995%+ Niobium content, complies with ASTM B392 standards

Stable up to 2468°C

Comprehensive specifications for our precision Niobium Wire products

| Parameter | Specification | Tolerance |

| Wire Diameter | 0.1mm - 5mm | ±1μm (for <50μm) |

| ±1% (for >50μm) | ||

| Length | Up to 1000 meters on spools | - |

| Purity | 99.95%, 99.99%, 99.995%+ | - |

| Surface Finish | Bright annealed or as-drawn | Ra < 0.05μm |

| Tensile Strength | 240-340 MPa (annealed) | ±10 MPa |

| 500-700 MPa (cold worked) | ||

| Elongation | 20-30% (annealed) | ±2% |

| 2-5% (cold worked) | ||

| Straightness | 0.5mm per meter | - |

Exceptional characteristics that make Niobium Wire ideal for demanding applications

Niobium possesses a unique combination of properties that make it indispensable for advanced technological applications. Our high-purity Niobium Wire maintains these properties consistently across production runs.

With a melting point of 2468°C (4474°F), Niobium Wire maintains structural integrity in high-temperature environments.

Resistant to most chemicals at room temperature and forms a protective oxide layer at elevated temperatures.

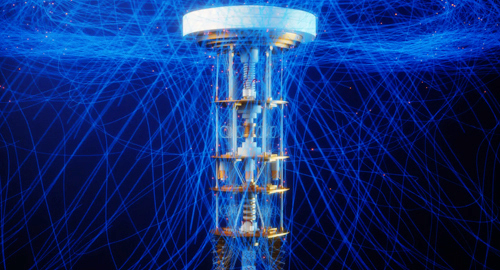

Becomes superconducting below 9.2 K (-263.95°C), making it valuable for cryogenic applications.

Niobium Wire can be drawn to extremely fine diameters while maintaining consistent mechanical properties.

Where our precision Niobium Wire delivers exceptional performance

Niobium Wire can be used as critical component in superconducting magnets for MRI machines, particle accelerators, and fusion research.

Ultra-fine Niobium Wire for precision medical instruments, implantable devices, and diagnostic equipment.

Niobium Wire can be used as high-temperature wire components for aerospace propulsion systems and satellite technology.

Niobium Wire can be used as precision wire for high-performance electronic components and specialized sensors.

Niobium Wire can be used as components for advanced energy storage systems and high-temperature fuel cells.

Niobium Wire can be used as specialized wire for laboratory equipment, particle detectors, and material science experiments.

Advanced production processes ensuring exceptional quality and precision

Multi-stage diamond die drawing process achieving ultra-fine diameters of Niobium Wire with exceptional dimensional control.

Controlled atmosphere heat treatment to optimize mechanical properties and reduce internal stresses of Niobium Wire.

Continuous diameter monitoring and surface inspection using laser measurement systems.

Class 1000 cleanroom environment for processing and packaging of critical application Niobium Wire.

Our technical specialists are ready to assist with your Niobium Wire requirements